Photo: iStock/viiwee

Editor’s Note: Click here to download the PDF and/or view in a slideshow vintage termiticide reports from 1951.

The U.S. Forest Service testing program has provided standardized test data on soil-applied termiticides for eight decades — and counting.

Pest Management Professional (PMP) Hall of Famer Dr. T.E. “Tommie Termite” Snyder joined the U.S. Department of Agriculture’s (USDA’s) Bureau of Entomology soon after receiving his master’s degree from Yale in 1909. In 1934, he was transferred to New Orleans to establish the Forest Entomology Laboratory at the Southern Forest Experiment Station, considered to be the first such lab in the South. As his industry nickname suggests, the-then 49-year-old Dr. Snyder was keenly interested in forest insects — subterranean termites in particular.

It was Dr. Snyder who hired Dr. Harmon “Johnny” Johnston in 1938, appointing him as a research entomologist on the Harrison Experimental Forest, near Gulfport, Miss. During his tenure, Dr. Johnston developed the groundboard test and began studies using this method. Data from these tests provided the U.S. military with a means of controlling termite infestations in wooden storage containers and (semi) temporary buildings built during World War II. Because of increased termite pressure and different species compared with North America, this information was of great importance in the Pacific theater.

The USDA’s Forest Service’s (USFS’) termite unit continued this work after the war, providing efficacy data for various candidate termiticides. This effort continues today, although the methods have evolved to incorporate the concrete slab test, in addition to the original groundboard test. What follows is the formal summary of the USFS’ annually collected termiticide field efficacy data for 2017.

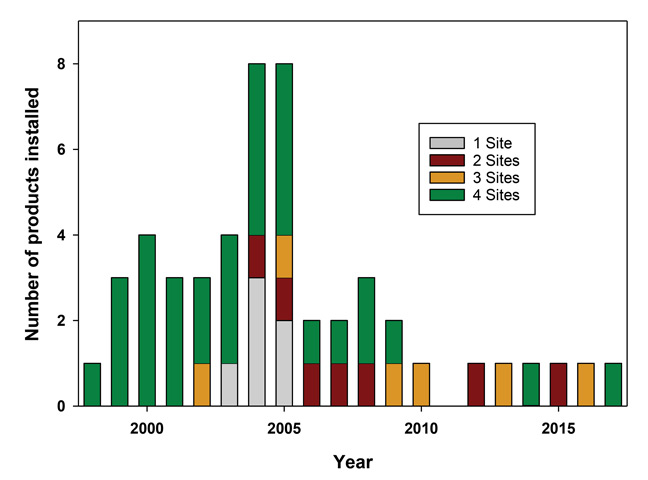

Fig. 1. Number of candidate termiticides installed each year by the USFS termiticide testing program. Chart: USFS

Program status

Fig. 1 illustrates the number of products installed by the USFS testing program each year, separated into products installed per site, which is necessary to accommodate mid-year installations. The report also includes two tables that provide data for the currently federally labeled termiticides on the U.S. market today.

Occasionally, a candidate termiticide manufacturer will decide to withdraw a product from testing. Our policy has been to not report on any products that do not obtain federal registration; due either to withdrawal or a product’s failure to meet the U.S. Environmental Protection Agency’s (EPA’s) performance standards. This prevents confusion and possible off-label use of agricultural products that share the same active ingredient as a candidate termiticide that did not obtain federal registration. As a result, the numbers in Fig. 1 will likely always be greater than or equal to the actual number of reported products in the report tables.

While originally providing potential termiticide product efficacy data to the military at its inception 80 years ago, the program now works with cooperators from the chemical industry — seeking efficacy data to satisfy federal registration requirements for potential new products. We offer installation and reading of plots using the groundboard, concrete slab and stake methods, as well as pesticide residual soil samples as an unbiased third party.

The EPA requires efficacy data for candidate products for five years. The studies take six years to complete, from product installation to completion. Each year, we provide product manufacturers with updates on their respective products’ performance.

The EPA provides termiticide efficacy testing requirements in two documents: OPPTS 810.3600 and the Pesticide Registration Notice 96-7. In those documents, the methods required by the agency are the same as those developed and currently used by the USFS, as described above. Over the past 80 years, the USFS termite unit has used a variety of national sites and one international location. Currently, the following sites are in use:

⦁ Chipola Experimental Forest in northwestern Florida.

⦁ Harrison Experimental Forest in southern Mississippi.

⦁ Calhoun Experimental Forest in western South Carolina.

Native subterranean termite species belonging to the genus Reticulitermes occur at these sites; thus, our test data only applies to members of this genus. For a discussion of the loss of our fourth site in southern Arizona, please refer to our report from last year.

Considering the number of available soil-applied termiticide products in the market each year, the data from Fig. 1 represent an early look at cycles of product availability. In other words, since we start working with new products six years before market availability, the number of products we install each year provides an estimate of how the termiticide market may look in roughly five to six years. Of course, not all products will gain registration, and others may be removed from the market because of business or other considerations. From that standpoint, it is always good to see new candidates entering the study process, as it indicates more options for termite control down the road.

In 2017, the USFS Termiticide Testing Program installed one new product at three sites. Currently, four candidate termiticides are being evaluated in

the testing program.

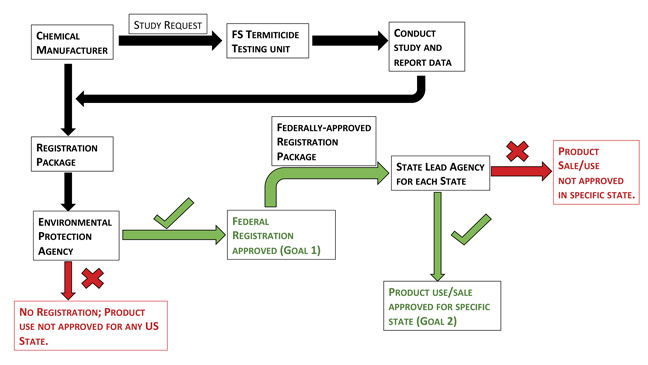

Chart: USFS

A termiticide regulation primer

In 1910, the U.S. Congress passed the Federal Insecticide Act, which regulated pesticide use in the United States. In 1947, the regulation of insecticides, fungicides and rodenticides (warfarin, etc.) was revised under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA). FIFRA gave the U.S. Department of Agriculture (USDA) the authority to regulate commercial pesticides. This continued until 1972, when Congress revisited pesticide regulation, moving the regulation of commercial pesticides to the U.S. Environmental Protection Agency (EPA). Part of the new agency’s responsibilities included regulation of commercial pesticides and their proper application (see chart at above).

Currently, pesticides are regulated by the EPA at the federal level, and by state lead agencies at the individual state level. State lead agencies are often state departments of agriculture, but not always, hence the name. These agencies use the same data used by the EPA to determine efficacy of those pesticides that require such data (termiticides and public health pesticides), and decide whether a new federally approved pesticide can be sold or used within a particular state’s borders. Many states work together on regulatory issues as part of the Association of Structural Pest Control Regulatory Officials (ASPCRO).

Fig. 2. Shawn Cooper, foreground, and Dr. Thomas Shelton clear plot areas of debris. Photo: USFS

Test methods

Evaluations of soil-applied termiticides are specified by the EPA in its Product Performance Test Guideline – OPPTS 810.3600. There are currently two accepted protocols for testing these products: the groundboard test and the modified groundboard (or concrete slab) test. Ten replicates of each concentration, including water-only controls, are installed for each candidate termiticide in each of the three national field sites.

The methods are described in the annual termiticide report each year. When few procedural changes have been made, the language used to describe them will be similar.

For the groundboard test, a 17×17-inch area is cleared of debris, roots and rocks (see Fig. 2) and treated with the candidate termiticide. After drying, a 6×6-inch square pine sapwood board is centered on the exposed, termiticide-treated soil, and held in place with a brick.

Fig. 3. Craig Bell places a vapor barrier on a treated concrete slab plot. Photo: USFS

The concrete slab test is very similar. In this test, the treated plot area is also 17×17 inches square and cleared as described above. After treatment (see Fig. 3), the soil is covered by a polyethylene vapor barrier, and a 21×21-inch concrete slab is poured around a 4-inch-diameter polyvinyl chloride (PVC) pipe placed at the center. Once the concrete has set, the vapor barrier is cut out and removed from the bottom interior of the pipe, and a 3.5×2.5×1.5-inch rectangular pine sapwood block is placed on the treated soil at the bottom of the pipe. To prevent weathering of the treated soil, a PVC cap is placed on the pipe. Completed plots form a grid in the forest (see Fig. 4).

For both methods, solutions of candidate termiticides are applied to the soil at the pre-construction rate of 1 gallon per 10 square feet in both test types. For each plot, the wood is evaluated for termite damage annually using a simple scale called the Gulfport scale, and the presence or absence of live termites infesting test blocks or boards is noted.

Damage data are collected using the Gulfport scale: 0 = no damage, 1 = nibbles-to-surface etching; 2 = light damage with penetration; 3 = moderate damage; 4 = heavy damage; and 5 = board or block destroyed.

Fig. 4. This completed block of plots resides in the Chipola Experimental Forest in Florida. Photo: USFS

Soil sampling

Since 1998, the testing program has included extra groundboard and concrete slab plots for pesticide residue analysis at each concentration level of a newly installed product. Soil sample cores are 1 inch in diameter and 4 inches in length, collected both after installation and on each subsequent year of the study. The groundboard and concrete slab plots designated for soil samples, however, have no wood blocks in the plots, so they are not read for termite damage.

The soil samples are then given to the respective product manufacturers for residue analysis of their products. These results can provide a timeline of product longevity and soil penetration depth at each time period for the product manufacturers.

Fig. 5. From left are Dr. Juliet Tang, Dr. Thomas Shelton, Blossie Boyd and Tina Ciaramitaro. Photo: USFS

Performance standards

As has been reported in previous annual termiticide reports by the USFS (PMP, 2016 and earlier), there is a single standard for federal registration under the EPA, and each state has the opportunity to create its own standard. As mentioned in the primer section, the lead agency for structural pest control in each state makes decisions regarding the use or sale of a product, via either a state-specific regulatory standard — such as the Florida Termiticide Efficacy Rule, 5e-2.0311, FAC — or its own judgment of the USFS efficacy data on the product. State lead agencies may also choose to make these decisions collectively through the Association of Structural Pest Control Regulatory Officials (ASPCRO).

For the USFS annual termiticide reports, the data in Tables 1 and 2 are presented for each site individually, as evaluated using the EPA guideline, and as an example of a state standard, the Florida Rule — individually by site and collectively across all southeastern sites. Discussions of the differences between the two standards have been covered in many of the past annual reports.

Fig. 6. Team members lead debris onto the tractor. Photo: USFS

Cleanup at the Harrison Experimental Forest

The Harrison Experimental Forest has been in use by the USFS termiticide testing program since its inception in 1938. For 80 years, our unit has been performing efficacy testing for soil-applied termiticides, termiticide impregnated barriers, physical barriers, and even some of the early attempts at area-wide termite control using Mirex baits in the 1970s. As has been discussed in previous reports, this work takes up many acres of land, which, depending on the nature of the product tested, may not be reused for testing purposes.

Fig. 7. Each dumpster contained 4 tons of concrete debris for disposal. Photo: USFS

In 2017, our unit began a process of dismantling older studies that are no longer being evaluated (see Fig. 5). These studies consisted of older physical barrier tests that were not impregnated with termiticides. Concrete blocks and barriers were removed from the study areas and hauled out of the forest in dumpsters. Some of the concrete blocks could be reused for future studies of this type and were saved, but the rest were sent to the landfill. In total, an estimated 8 tons of concrete and debris were removed from the forest over the course of a week in April 2017 (see Figs. 6 and 7). Clearing will continue in June 2018.

As we reported in the 2005 report (PMP, Feb. 2006), Hurricane Katrina damaged much of the forest canopy cover through treefall at the Harrison Experimental Forest. While this only affected a few plots of our studies, it encouraged a larger problem: undergrowth (see Fig. 8). In the years that followed, undergrowth grew quickly in areas where sunlight shone through the partial canopy. These areas became thickly overgrown, and often required days of clearing to install new plots and examine old ones. It will be many years before new trees will reach canopy height and slow the process down.

Fig. 8. Typical undergrowth on the Harrison Experimental Forest (April 2017). Photo: USFS

This experimental forest is home to research on many fronts, both within the USFS — the Forest Genetics and Ecosystem Biology work unit (SRS-4160) since 1954, and wood preservative studies conducted by the Forest Products Laboratory in Madison, Wis., since 1938 — and with outside cooperators such as Mississippi State University. Now that the termite unit in Starkville has merged with Durability and Wood Protection Research of the Forest Products Laboratory, we have an increased need for clearing undergrowth on the Harrison Experimental Forest for new studies — and collecting data on old studies.

Why did we remove the concrete? The concrete prevents any type of mechanical clearing of underbrush (by using a tractor and “brush hog,” for example). Opening up the undergrowth can be done by hand, but requires more manpower than our eight-person staff based in Starkville has available. We believe our first cleanup effort was a success (see Fig. 9), but there is much more clearing that still needs to be done.

Fig. 9. A single plot lane after clearing debris and vegetation. Photo: USFS

Conclusions

The USFS termiticide testing program has served the American public and pest management industry for 80 years, providing unbiased candidate termiticide efficacy data for state and federal regulators. The testing program has provided performance data for all termiticides currently registered in the United States. These reports provide efficacy data of registered termiticides to the pest management industry, pesticide manufacturers, government regulators, and the American consumer. By making this data publicly available, the USFS enables people to make informed decisions concerning the protection of the wood framing in their homes and outdoor structures from termite damage. For the foreseeable future, the USFS termiticide testing program will continue to provide information about these products.

Leave A Comment