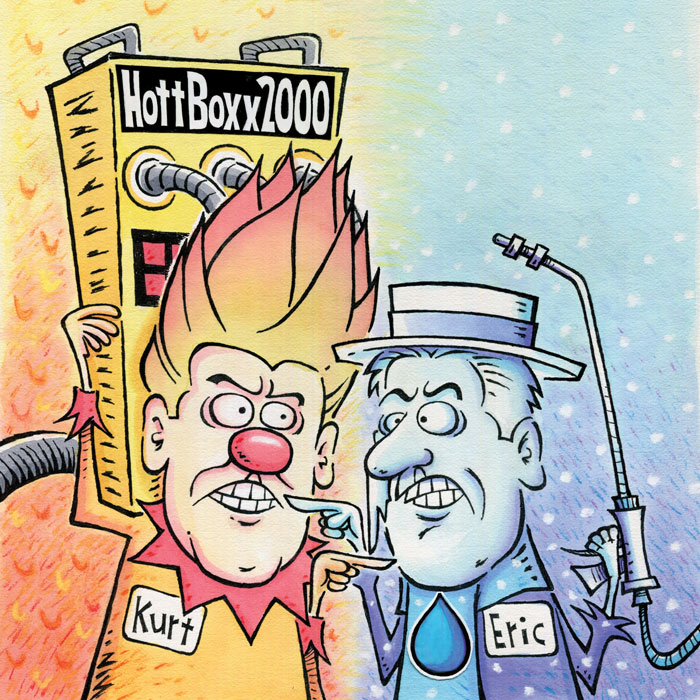

Illustration: Leo Michael

Who doesn’t love a little controversy? We certainly do. That’s why we pitted our “Face-Off” columnists — Scherzinger Termite & Pest Control’s VP of Sales & Marketing, Eric Scherzinger, and his brother, VP of Operations Kurt Scherzinger, ACE — against each other, knowing their Cincinnati, Ohio-based firm uses both bed bug treatment methods: heat, which they often follow up with a chemical application for residual control, and chemical. Although plenty of bed bug management options exist, this debate explores the differences between heat and chemical treatments for bed bugs. Let the debate begin! — The Editors

Read the other side: “AN APPEAL FOR TRADITIONAL TREATMENT” by Eric Scherzinger

AN APPEAL FOR HEAT

By Kurt “Heat Miser” Scherzinger, ACE, PMP Contributor

Let’s face it: We have to stay ahead of the curve with new technologies that eliminate the pests we combat every day. If not, we could fall behind and lose our competitive edge.

We always have tried to use modern technology on the pests we aim to control. Look at termite baiting, electronic rodent monitoring, and the software associated with it all. That’s why I’m an advocate for heat treatment for bed bug management.

PHOTO: iStock.com/sbayram

Cost vs. benefits

My brother may point out that heat units need maintenance and service from time to time. At Scherzinger Termite & Pest Control, we have a strategic partner that works on our complex equipment for us, and the heat units are no exception. That way, highly trained experts make repairs that meet code so our employees are safe when operating all our equipment.

The heat method may cost customers a little more than other bed bug control techniques. On the other hand, they typically get a little more for the service.

Heat is more convenient for customers because it often requires less preparation. Plus, customers only have to be out of the house once vs. many times for all those follow-up service calls required with chemical treatments.

The heat method enables technicians to conduct a thorough inspection from the start by virtue of moving around affected items. Heat gives technicians more control because they are moving infested items. Once the customer’s items are all moved, the surroundings are conducive to performing a residual chemical application, too — thus increasing the longevity of effectiveness.

We always have used electric generators to power our heating devices. When we first offered the heat method, we felt it was the safest route to go. All systems are safe when monitored correctly; however, with multiple crews out on a daily basis, we tried electric. Because we have not had any issues, we chose to stick with it.

PHOTO: Scherzinger Termite & Pest Control

Overcoming objections

To assure customers who may be worried about technicians moving their personal items, an important part of the process is communicating, up front, exactly what needs to be removed from the premises. After all, we are going to be heating their houses to 135°F. We do not want to be responsible for anything that might melt or explode at temperatures that high, so we give customers a list of the items they need to remove and plenty of time to remove them. By the time we get there to perform the service — even if part of the plan is to have our technicians take down curtains and perform other prep work — it is no different than treating for any other pest. We also conduct a walkthrough with the customer before the heat treatment begins, to make sure any problematic items are removed. But other than that, we can resolve issues while they are at work for the day.

For technicians who are worried they’re going to be working in sweltering temperatures, rest assured we consider our employees to be our No. 1 asset. We put procedures in place to limit the amount of time they spend in the heat, and require them to use a buddy system that ensures they are safe at all times and always accounted for.

We also place wireless monitors throughout the structure to track temperatures and record ambient air temperatures. Doing so ensures the room reaches the proper “kill temperature.” This way, we gain the customer’s confidence that every bed bug — from egg to adult — is killed while we are there.

Keep in mind, bed bugs can harbor almost anywhere. Heat treatments replace any airspace with hot air to eventually kill anything hiding in an infested area.

All treatment methods can be effective if implemented correctly, and detail-oriented technicians are key. It all starts with hiring the right people.

Heat treatments are very specialized, so our technicians who are trained in this method also assist with other specialty services, such as liquid barriers or mosquito work. Our general pest control technicians perform chemical work for customers on their assigned routes, and sometimes they will help with follow-up inspections for heat treatments. All of our technicians receive four weeks of training that includes a mix of classroom and field instruction before they start work in their respective departments. We hold monthly meetings during which our team reviews various aspects of the business, including all methods of bed bug eradication — even those we may not offer — so they are aware of the bed bug management options out there.

The science behind heat

Some heat treatment systems use electric heaters to generate the heat, blown in by fans; others use propane heaters, blown in through existing ductwork. Both methods get the room temperature to the “magic number” of 135°F, which can control bed bugs but not damage most household goods, including electronics.

The room’s temperature is maintained for several hours. The temperatures in cracks, crevices and hard-to-reach places are monitored remotely by numerous sensors placed throughout the room(s). Once the adult bed bug thermal death point is reached at all the sensors (114°F to 115°F), the heating process is continued for 60 minutes or more to kill all of the bed bugs and their eggs. The advantages of these heat systems are that the residents do not have to remove or bag their belongings, and most infestations can be managed in a single treatment. The heat treatment process usually takes six to eight hours, from setup to takedown.

Heat treatment is one of the few methods that can be used alone for bed bug control. However, some buildings (usually older, remodeled buildings) may have construction features that create heat sinks. In cases where construction issues are a concern, it is wise to supplement the heat treatment with a conventional insecticide application in cold spots where bed bugs might find refuge.

SOURCE: Virginia Department of Agriculture and Consumer Services’ bulletin, “Non-Chemical Bed Bug Management,” written by Dr. Dini Miller and available online at VDACS.virginia.gov/pdf/bb-nonchemical1.pdf

5 reasons heat is hot

- Fewer visits often are needed to perform heat treatments when compared with chemical treatments.

- Success can be achieved despite a customer’s clutter, whereas they may not be viable candidates for chemical treatment.

- Heat treatments require less customer preparation.

- Customers looking for an environmentally friendly solution may prefer heat treatments.

- Heat treatments are performed by specialized, highly trained teams of technicians.

Read the other side: “AN APPEAL FOR TRADITIONAL TREATMENT” by Eric Scherzinger

Brothers Eric and Kurt Scherzinger are vice president of sales and marketing and vice president of operations, respectively, for Scherzinger Termite & Pest Control based in Cincinnati. The fourth-generation pest management professionals can be reached at eric@stopzbugs.com and kurt@stopzbugs.com.

Leave A Comment