Denver Branch Manager Kolbin Bertilson, ACE Photo: Kevin Snyder Photography

Last fall, Tacoma, Wash.-based Sprague Pest Solutions unveiled a new space for its service center in Denver, Colo. The 7,000-square-foot facility was built in the 1960s as a warehouse, but as renovated today, it now stands as a model for future Sprague locations. Among its highlights are:

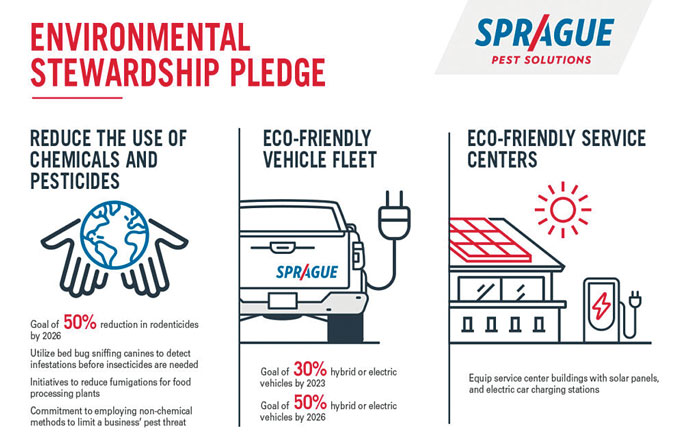

- 40 solar panels on the roof, allowing the office to operate almost completely off the grid.

- All lights and air systems in the facility are automated to be in use or change behaviors as areas are occupied.

- A state-of-the-art training room can host up to 45 people — fully equipped with surround-sound, two monitors, and an eat-in serving station.

- The training room is at the center of the facility and features a fully glass wall so if someone needs to step out into a hallway for a phone call, etc., the video screens are still visible.

- 13 cubicles, three private phone booth workspaces, two offices and three conference rooms.

- Electric vehicle charging stations assist with the goal of the company’s overall fleet being 50 percent hybrid or electric by 2026.

A sunny start

PHOTO: SPRAGUE PEST SOLUTIONS

“Colorado has an annual average of 300 days of sunshine, so equipping this building was a no-brainer,” notes Denver Branch Manager Kolbin Bertilson, ACE.

Bertilson says the “marketing” of Sprague as a green pest control company starts as soon as a technician rolls up in a hybrid or electric vehicle to the account. “It immediately helps us stand out,” he says.

Customer communication is another important facet of being a green-focused company, Bertilson says, especially since Sprague has all commercial accounts. There may be regular visits, but there are also often new faces at the account who may need to be familiarized with the pest management and prevention approach.

“The technicians enjoy teaching our customers about the positive ways we can perform our work with less environmental impact while actually improving pest control results,” he points out. “We often get team members inviting our customers to our office for business training, a lunch

and learn, or a simple friendly visit where we can show them the building and explain what we’re really all about.”

Ross Treleven

Ross Treleven, the fourth-generation president of Sprague, admits he is partial to the Denver branch because he served as its first branch manager in 2011.

“Back then, we had six people sharing a very small office, and conducted our training in the warehouse,” he recalls. “There’s nothing wrong with that, of course, and several of our offices are still set up that way. But this office has really arrived, and is our pilot program for how we will design our locations in the future, whether it’s new growth or time to remodel an existing building.”

Supply vs. demand

Ross says Sprague is still looking to equip half of its fleet with hybrid and electric vehicles by 2026, but the current supply volume is not helping. “Some vehicle brands have kept up with demand; others have not,” he laments. “We also account for rural routes, where going full electric might not make sense.”

PHOTO: SPRAGUE PEST SOLUTIONS

Still, he says, contrary to common conceptions, focusing on environmental stewardship can help the bottom line in the long run.

“We think we can attract customers to our brand because of our approach,” Ross points out. “It’s just as much of a brand decision as it is an environmental decision. That’s because right now, it’s still largely an unoccupied space in our industry, and it’s easier to pivot a company of our size than a bigger company — or even a smaller company with tighter margins. We can stand out, and we are happy to capture that part of the market.”

A.J. Treleven, ACE

A.J. Treleven, ACE, another fourth-generation Sprague leader and its director of operations, agrees. With so many commercial and industrial requests for proposal (RFPs) featuring entire sections detailing what they want regarding the use of pesticides and the carbon footprint, focusing on being as green as possible “is now a differentiator in our value proposition,” he says.

Being an environmental steward is often a matter of doing so mindfully wherever you can. “We have solar panels for our offices in Denver; Boise, Idaho; and Portland, Ore.,” he offers as an example. “But it doesn’t make sense to use them in rainy Seattle, where hydroelectric dams mean our electric is practically paying for itself.”

Advice for going green

“Be curious and ask questions,” A.J. advises when looking to implement green initiatives. “Don’t assume. Will it fit within your goals and what you think is important? As a business, we vote with our dollars.”

A.J. also notes that being environmental stewards is just baked into what Sprague is today. “We believe in science, and we think we should do our best to lean into that science in every aspect of our business,” he concludes. “In addition to the ‘low-hanging fruit’ of solar and hybrid fleets, can you and your team answer why you choose each treatment you do? Why are you running a route this way? If you don’t know, find out. The answer should be that it is the optimal way from both a cost and environmental standpoint.”

Environmental Impact

Sprague Pest Solutions

Denver Branch Manager Kolbin Bertilson, ACE, reports three impressive stats based on the office’s solar panels:

- 129,000 pounds of carbon dioxide emissions saved, January 2022-August 2023

- 29.3 megawatt-hours of solar power generated January 2023-August 2023

- 83.9 megawatt-hours of solar power generated January 2022-August 2023

Company name: Sprague Pest Solutions

Headquarters: Tacoma, Wash.

Service ratio: 100% commercial

Year founded: 1926

Kolbin Bertilson, Denver branch manager, advises: “Gas is such an unpredictable force. With the recent ups and downs of oil prices, it’s hard not to analyze fuel costs. In addition to ordering electric and hybrid vehicles, it’s easy to use a phone app that shows you the closest and cheapest gas stations while on the road. Fleet data is another powerful tool to help reduce your fuel consumption. Even small tweaks like avoiding traffic can make a big impact.”

Sprague’s rodenticide reduction initiative

When Ashley Roden, BCE, began as a technician at Sprague in 2013, the company had an industry-typical approach to rodent control at commercial accounts: Place indoor and outdoor bait stations on initial visit; check stations with a scanner every subsequent visit; replace with new bait and document how much at every station.

Ashley Roden

But a few years later, when the Tacoma, Wash.-based company expanded to California, Roden recalls how “we got our first taste of rodenticide restriction, and surprisingly, we were able to follow the rules and still get control.”

She notes that with the help of Sprague’s director of operations, A.J. Treleven, ACE, the team decided it was time to stop putting new bait in every outdoor station as though they were on autopilot and start thinking about each station’s independent status. In addition, pulse baiting on interior stations — using a non-toxic monitoring bait to identify how much activity is occurring before switching to rodenticide bait — is now the main focus indoors.

The mantra Treleven has implemented is “There must always be a why.”

“If there has been no activity for 12 months in an outdoor bait station — feeding, droppings, etc. — you shouldn’t have rodenticide there,” explains Roden, who today is Sprague’s technical and quality assurance manager. “Switch to a non-toxic bait or a snap trap.”

An added benefit to this approach, she adds, is that stations that have had a year of no activity suddenly have a lot after the change. “Maybe they didn’t like the bait, or maybe it was only slugs and snails getting in, not rodents.

A simple change can make a huge difference,” Roden says.

When rolling out the approach more than a year ago, Roden says, it was a “suggestion” to technicians. As of January, it’s more than a suggestion — it’s policy. “This actually makes it easier for them because if the customer doesn’t like it, they can reach out to the manager,” she says, noting that one technician told her privately that he was relieved with the change, as 70 percent of his stations at a large account had no activity.

Overall, she says, customers appreciate the new approach, and so do others. “We had a third-party auditor come up and specifically tell us he likes this strategy,” she reports. “It might be a slow change to accept, but we feel good about this more logical approach that has also saved money on bait. Thinking this way has driven our team to explore even more innovation. We are continually trying to answer, ‘When is rodent control appropriate? What are other things we can do?’”

For more information on Sprague’s approach to rodent control, visit SpraguePest.com/the-evolution-of-rodenticide-replacement.

Leave A Comment