Fig. 1. Early plot layout in the field at the Harrison experimental forest (HEF). Once a rectangle with 90-degree angles is in place, individual plots can be assigned. (PHOTO: US DEPARTMENT OF AGRICULTURE FOREST SERVICE)

Prior to use or sale, new termiticides must undergo a standardized test — and those efficacy data are subsequently submitted to the U.S. Environmental Protection Agency (EPA). The EPA has a specific methodology that is required for testing, and the agency relies on the U.S. Department of Agriculture (USDA) Forest Service (FS) Forest Products Laboratory Durability and Wood Protection unit to do the work. These data are used to determine whether tested concentrations, applied in the studies as a zone of treated soil, are effective at preventing damage to test wood blocks in three field locations in the southeastern United States.

The EPA requires five years of efficacy data, and at the end of those five years, accepts a registration package for that product containing those data. The data are examined, and a decision is made on what concentrations will eventually appear on the product label. As the label is the law, only those concentrations will be used in legal applications of the material.

The current report provides the data for currently registered products at their labeled application concentrations. This provides information about efficacy of these products to pest management professionals, state regulatory agencies, and owners of homes and/or other wooden framed structures. As described below, the FS takes observations at set points throughout the year. South Carolina plots are observed during September, which means the observations in the report represent the data collected during 2023.

As mentioned above, currently all the sites where the FS conducts these tests are in the Southeastern U.S. and are experimental forests (EFs), which are parts of national forests managed by the FS. The important part about EFs is that they are set aside for research and are not open to the public. Because the FS is testing candidate (unlabeled) termiticides to determine label rates, these studies cannot be open to the public where untrained persons could contact the treated soil.

Specifically, we work on EFs in Mississippi near Gulfport (the Harrison EF, or HEF); in Florida near Panama City (the Chipola EF), and in South Carolina near Clinton (the Calhoun EF). Of these EFs, the HEF is the most famous, as this is where the FS started the candidate termiticide studies in 1938.

The FS at one time had its laboratories in Gulfport, Miss., and the combination of the fieldwork at the HEF and the lab location is why the City of Gulfport is so strongly associated with the unit. Since 1996, however, the labs in Gulfport were moved to Starkville, Miss, to be near Mississippi State University, while the fieldwork remained on the HEF.

Within the plots, only native subterranean termites belonging to the genus Reticulitermes have been found on infested blocks. Therefore, our test data only reflect the response of Reticulitermes spp. to the candidate termiticides.

FS termiticide testing program status

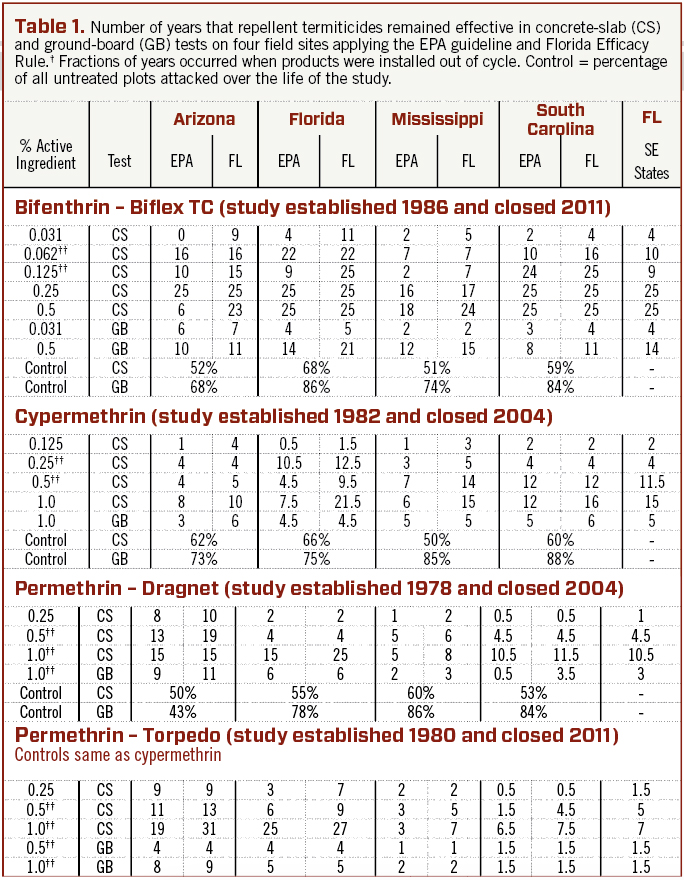

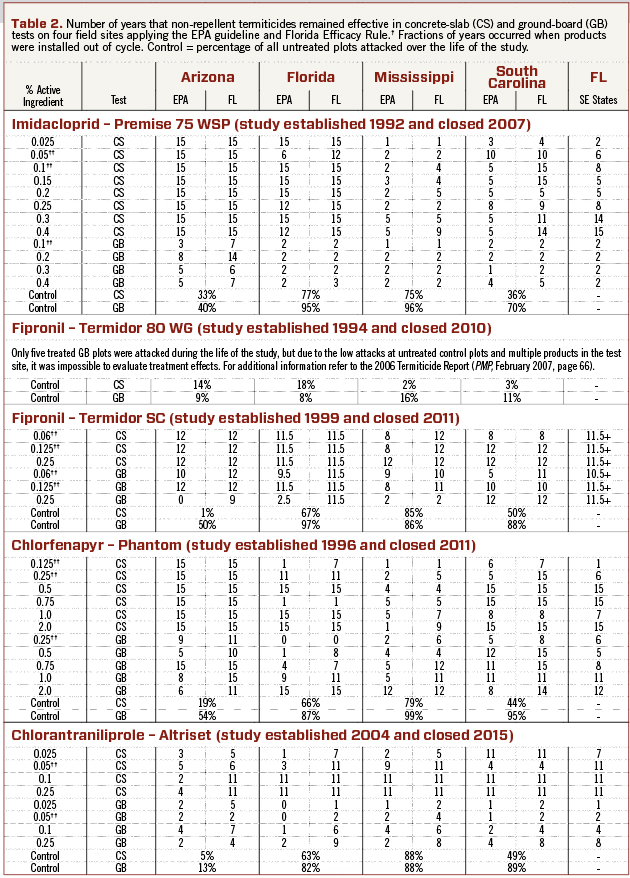

In 2023, two new products were installed at the FS termiticide testing sites, and evaluation continued for two other candidate termiticides. Tables 1 and 2 provide efficacy data for current, federally labeled termiticides in the U.S. Candidate products can be withdrawn from testing at any time by their manufacturers. Our policy is to only report data from federally registered products, and only at label rates. This prevents possible off-label concentration applications, as well as the use of agricultural products using the same active ingredients.

Manufacturer representatives request the FS termiticide testing program to provide product efficacy data as an unbiased third party. Collected efficacy data eventually will be included in a registration packet that is submitted to the EPA when seeking federal registration for the product. The products tested are the formulations that would eventually be made available commercially; the FS does not test active ingredients by themselves.

Fig. 2. Concrete slab soil sample (no PVC) plot during concrete pouring at the HEF in 2023. (PHOTO: US DEPARTMENT OF AGRICULTURE FOREST SERVICE)

During the field work, cooperator personnel can observe and assist to a limited extent, such as digging holes or clearing trees from a plot area. However, cooperators are not allowed to help with mixing product, treating plots or determining wood block damage (reading). All FS personnel who mix and apply candidate chemicals have current commercial pesticide applicator certificates (Category X) and many years of experience with the FS testing protocol.

The FS offers two tests for soil barrier efficacy for candidate products: the ground board and the concrete slab. The FS also provides samples of treated soil and conducts both product installation and annual observations of test wood. These methods are identical to those required by the EPA Office of Poisons, Pesticides and Toxic Substances (OPPTS) 810.3600 document. This document requires five years of efficacy data for candidate termiticides. As a result, these studies take a total of six years to complete.

Product manufacturers are updated annually on their product’s performance. The EPA, and eventually state regulatory agencies (once the product obtains federal registration) are free to contact the FS regarding the data or methods used to obtain them.

† EPA: years with no penetration through treated soil in any plot.

FL: years with no annual damage more severe than ASTM 9 to blocks or boards on 90% or more of the plots per site (each annual evaluation stands alone, not cumulative).

FL SE States: years with no annual damage more severe than ASTM 9 to blocks or boards on 90% or more of the plots across the southeastern sites (damage ratings are annual, not cumulative).

†† Registered label rates.

Test methods

The ground board test and the modified ground board (or concrete slab) test are specified for efficacy testing of candidate products in OPPTS 810.3600. Ten replicates of each concentration — including water-only controls — are installed for each candidate termiticide in each of three experimental forests, as described above. Individual plots are laid out within rectangular areas in the forest (see Fig. 1).

The methods are described in Pest Management Professional’s (PMP’s) annual termiticide report each year. Because no procedural changes have been made since 2017, the language used to describe them remains constant.

The ground board test employs a 24-by-24-inch area that is cleared of debris, roots and rocks. Then, a 17-by-17-inch area is treated with the candidate termiticide at the concentrations requested by the manufacturer, at the sub-foundation rate of 1 gallon per 10 square feet.

After drying, a 6-by-6-inch square southern pine sapwood board, provided by the East Mississippi Lumber Co. in Starkville, is centered on the exposed, termiticide-treated soil, and held in place with a brick.

In the concrete slab test, a 24-by-24-inch area is cleared and prepped as described above. A 17-by-17-inch area is treated as in the ground board test. After treatment, the soil is covered by a polyethylene vapor barrier (6 mil thick and 0.006 inch black construction film, Lowe’s item No. 810482), and a 21-by-21-inch concrete slab is poured around a 4-inch-diameter polyvinyl chloride (PVC) pipe placed at the center of the square (see Fig. 2).

Once the concrete has set, the vapor barrier is cut out and removed from the bottom interior of the PVC pipe, and a 3.5-by-2.5-by 1.5-inch rectangular pine sapwood block is placed on the treated soil at the bottom of the pipe. To prevent weathering of the treated soil, a PVC cap is placed on the pipe. Completed plots are laid out in a grid pattern within the forest.

Mixed solutions of candidate termiticides are applied to the soil at the pre-construction horizontal treatment rate of 1 gallon per 10 square feet in both test types. Wood placed in each plot is evaluated annually for termite damage using the Gulfport scale (described below); the presence or absence of live termites infesting test blocks or boards also is noted.

† EPA: years with no penetration through treated soil in any plot.

FL: years with no annual damage more severe than ASTM 9 to blocks or boards on 90% or more of the plots per site (each annual evaluation stands alone, not cumulative).

FL SE States: years with no annual damage more severe than ASTM 9 to blocks or boards on 90% or more of the plots across the southeastern sites (damage ratings are annual, not cumulative).

†† Registered label rates.

Soil sampling

During product installations, two extra ground board and concrete slab plots per concentration are added for soil pesticide residue analysis. One soil sample core per residue analysis plot is collected measuring 1 inch in diameter and 4 inches in length after initial installation and on each subsequent year of the study. After each soil core is taken, a 1-inch diameter PVC spacer is placed in the sampling location to prevent the same place from being sampled again later.

The ground board and concrete slab plots designated for soil sample collection have no wood blocks in the plots, and therefore cannot have termite feeding observations. The collected soil samples are shipped to the product manufacturer for residue analysis of its product.

The Gulfport scale

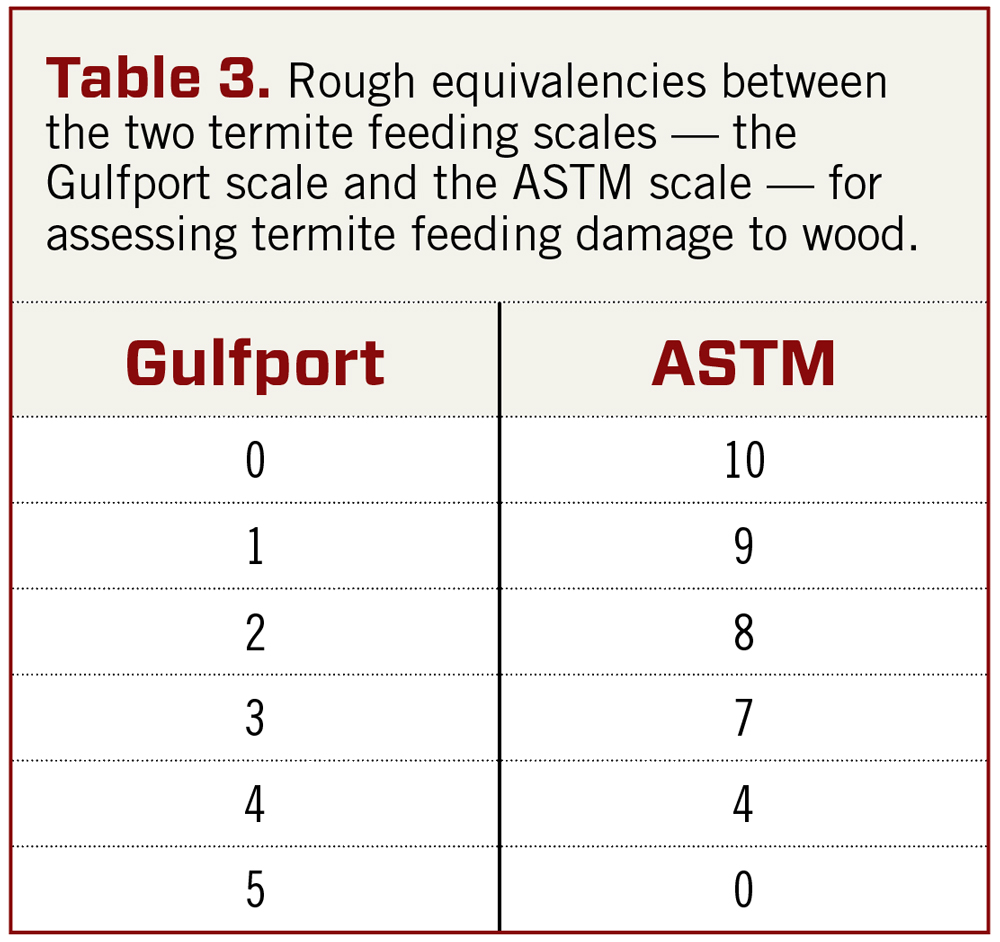

Termite feeding data is assessed using the Gulfport scale: 0 = no damage, 1 = nibbles-to-surface etching; 2 = light damage with penetration; 3 = moderate damage; 4 = heavy damage; and 5 = board or block destroyed.

The Gulfport scale was developed in the late 1930s by the FS termiticide unit to give an estimate of the level of termite feeding on wood examined when the study plot is annually evaluated. The scale was first published in 1959 by Dr. Arthur Verrall1. The Gulfport scale can be compared to other termite feeding standards, such as the ASTM laboratory wood damage scale in standard ASTM D 3345-222. Table 3 shows a comparison of the two scales.

The damage/feeding scales described are categorical and in nature, termite damage does not readily jump from one of these conditions to the next. Termite feeding would be more accurately represented if wood mass loss could be measured, but this is difficult to perform in the field in a short amount of time — and without the ability to equilibrate the wood block to a constant weight.

The rating scale system allows for fast collection of damage data. In the field, the block ratings also are not evenly distributed across these categories. This is partly because of the size of the categories, with three taking up both a substantial portion of the potential block damage, as well as the largest chunk of study data each year for products reaching the end-of-life date.

Regardless, while it might be possible to make statistical comparisons using non-parametric methods, these are unnecessary, as the standard established by the EPA is a pass/fail system. Furthermore, the categories can be important for state regulatory standards, which in some states can set percentages of allowable damage to blocks (see “Performance Standards” below).

Fig. 3. An example of the new method tube test. (PHOTO: US DEPARTMENT OF AGRICULTURE FOREST SERVICE)

Latest results

Archived data for all repellent (Table 1) and non-repellent (Table 2) termiticides, going back to 2013, are available online at MyPMP.net/tag/termiticide-testing-program. No new products entered the market in 2023, and all currently registered soil-applied termiticide products have had their studies closed at the request of their respective manufacturers. Thus, there are no new products whose data can be revealed and no additional data for currently available products can appear in the tables. The tables and data in this report are the same as the report published in PMP’s May 2015 issue. All recently collected data are for unregistered products, which remain confidential until after their EPA registration, and with an accepted label.

A comment should be made regarding the Altriset product, with the active ingredient chlorantraniliprole. Altriset still appears in Table 2 because it retains its federal registration for use in the U.S. The product is no longer being produced by its manufacturer, Syngenta Crop Protection, but remaining stock still can be sold and applied. The data are provided here should the public need them when considering Altriset use. It is expected that the remaining stock will diminish over time and the product eventually can be removed from Table 2.

New methodology

One of the key problems with the current test methods described above is that there is no way to predict termite activity at individual plots. We know termites are quite common in the EF locations, for example, and control data show that even without a way to assess termite activity ahead of time, “random” plots still show termite activity. However, even if all the plots in a study are active, there is no way to know whether any given plot has the same termite pressure as any other. Thus, something aside from field activity of the termites is needed to support our efficacy data.

Work by Dr. Kenneth Grace and his team in 19933 provided a method that could be modified to fit this purpose. Their work used samples of termiticide-treated soil packed into thin glass tubes, which had fixed numbers of termites added to the bottom. The tubes were examined over several days. This provided termite mortality data, as well as termite tunneling distance through the treated soil — all while using the same known degree of termite pressure for every tube.

The FS has modified the literature methods to suit the FS field trials. Basically, starting with a simple concrete slab for all plots, we take soil samples as described above at different time intervals. Our plastic tubes, as seen in Fig. 3, are wider than the glass tubes used by Dr. Grace and his team, but otherwise, the method is very similar.

We do not take observations of sample wood in the plots (as there is no wood to observe), and our observations are limited to the response of known numbers of termites in the tubes. Thus, we are getting the field aging of the product application, but the data come from known termite pressure, rather than by chance.

This method has just been put into practice this year as a test to determine whether it will work. The FS will make modifications along the way to improve the methods. Another benefit of the new method being examined is that the data are not categorical. Both mortality and tunneling distance could be analyzed through parametric means, assuming the data were normally distributed.

Conclusions

The USDA FS has provided unbiased candidate termiticide efficacy data for federal needs (military or regulatory) since 1938. To date, this program has provided performance data to the EPA for all federally registered termiticide products. These data are also provided to the public via this report. We hope this information enables the public to make informed decisions regarding the protection of wood in service from termite feeding and assists pest management companies in making decisions about which termiticide products to offer their customers.

Performance Standards

As we have noted in previous reports published in Pest Management Professional (PMP), the U.S. Environmental Protection Agency (EPA) has a single standard for termiticide efficacy: five years of complete control. In other words, there is no termite attack to any plot’s wooden block.

While there is a single federal standard, states can create their own standards. The individual state lead agencies for structural pest control make decisions regarding the use or sale of a product via either a state-specific regulatory standard (such as the Florida Termiticide Efficacy Rule, 5e-2.0311, FAC), or using their own judgment of the Forest Service (FS) efficacy data on a product. Several state lead agencies have chosen to make these decisions collectively through the Association of Structural Pest Control Regulatory Officials (ASPCRO).

In this report, the data in Tables 1 and 2 are presented for each testing site individually, using both the EPA guideline and the Florida Rule (individually by site and collectively across all sites). Discussions of the differences between the two standards have been covered in many of the past annual reports, particularly in the April 2016 issue of PMP. Both standards have remained unchanged in the meantime.

References

- Verrall, Arthur F. 1959. “Preservative moisture-repellent treatments for wooden packing boxes.” Forest Products Journal. 9(1): 1-22.

- ASTM (American Society for Testing and Materials). 2022. D3345-17. “Standard test method for laboratory evaluation of wood and other cellulosic materials for resistance to termites.” ASTM Annual Book of Standards. Vol. 04.10, West Conshohocken, Pa.

- Grace, K.J., J.R. Yates, M. Tamashiro, & R.T. Yamamoto. 1993. “Persistence of organochlorine insecticides for Formosan subterranean termite (Isoptera: Rhinotermitidae) control in Hawaii.” J. Econ. Ent. 86(3): 761-766.

Editor’s Note:

For Tables 1 and 2, the data for the program that can be made public at press time have remained the same since they were first printed in the March 2015 issue of Pest Management Professional magazine. Please note the inclusion of brand names and manufacturer names are for data purposes only, and does not imply endorsement by the USDA-USFS.

Leave A Comment