Don Fye fills a frame with concrete, while Craig Bell holds the PVC pipe in place. The capped pipe serves as an easy and repeatable means of accessing the test block while leaving the concrete slab in place. PHOTO: USFS

Each year, the U.S. Department of Agriculture’s (USDA’s) Forest Service Forest Products Laboratory, Durability and Wood Protection research work unit (FS RWU 4723) installs and/or observes plots of soil treated with candidate termiticide products. These products may or may not be available to pest management professionals (PMPs) for application, depending on federal and state registration.

This article reports on the latest results of these studies, and provides data for those products that have reached federal registration. Data provided are limited to label-approved rates of application for these products. This article provides information for PMPs as well as homeowners, but limits the data to only those application rates legal to apply. Because the U.S. Forest Service (USFS) observes some plot locations late in the calendar year, the previous year’s data are reported in each publication (for example, this article will report on data collected in 2020; the 2019 data appears in the August 2020 issue of Pest Management Professional, or PMP). The Forest Products Laboratory is maintained in cooperation with the University of Wisconsin, Madison, Wis.

This has been a long-term set of studies. The program began in 1938 for the military, on plots located in the Harrison Experimental Forest near Gulfport, Miss. While the number of locations has expanded and reduced over the years, the Gulfport location has always been the nucleus of our program. Currently, two other test sites are in use: the Chipola Experimental Forest in northwestern Florida, and the Calhoun Experimental Forest in western South Carolina. Because only native subterranean termite species belonging to the genus Reticulitermes occur at these sites, our test data only applies to members of this genus. Incorporating multiple test sites increases information on how well these treatments perform under varied climates, soil types and in differing geographic regions.

2020 RESULTS

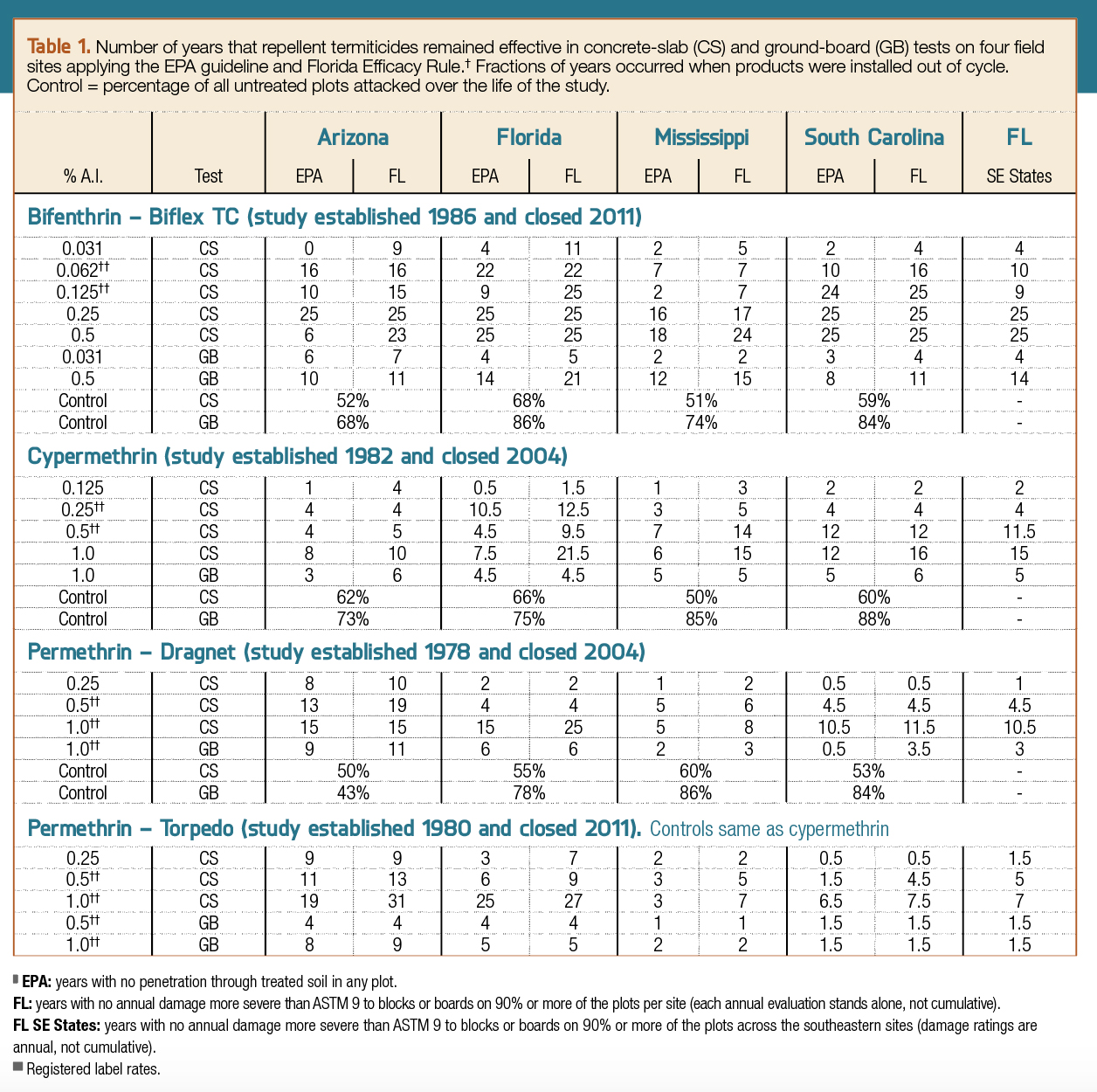

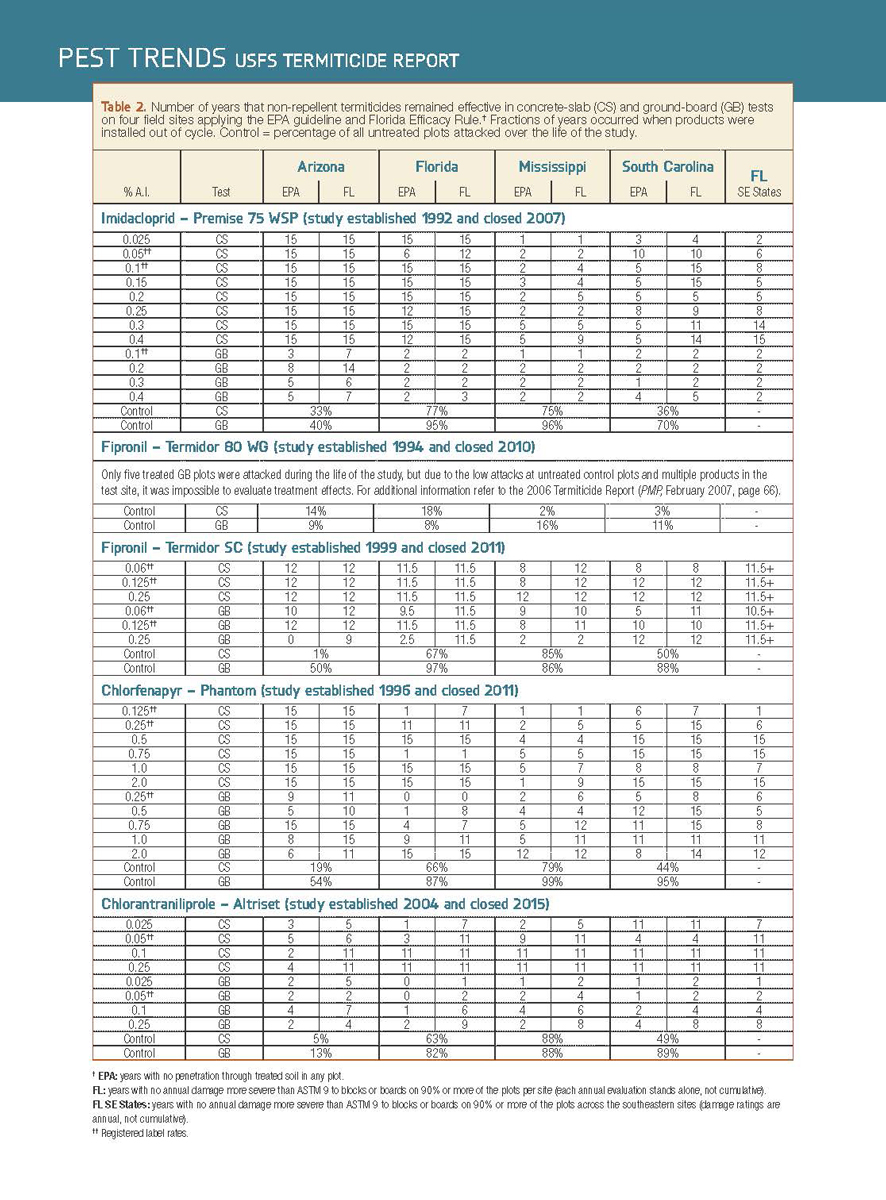

In 2020, no new products were installed at the USFS termiticide testing sites. Two candidate termiticides continue to be evaluated. This report includes two tables providing data for all of the current federally labeled termiticides in the United States. Manufacturers of these candidate products can withdraw products from testing for any reason at any time. Our policy has been to not report on any products that do not obtain federal registration; therefore, no withdrawn products or those that the U.S. Environmental Protection Agency (EPA) rejects appear in the data tables of this report. This prevents confusion and possible off-label use of agricultural products that contain the same active ingredient.

All recently collected data are for the two as-yet-unregistered products remain confidential until after registration. Data were collected in 2020 as planned, following USFS rules for protecting employees from the COVID-19 virus.

OVERALL METHODS

The goal of the USFS termiticide testing program is to provide unbiased, third-party data on efficacy of candidate termiticides in cooperation with the manufacturers of those products. The efficacy data is gathered for eventual inclusion into a registration packet that will be submitted to the EPA seeking federal registration. These tests begin when cooperators bring a candidate product to the USFS, and suggest the concentration series they are interested in pursuing. From there, the company personnel may observe and assist with the study to a limited extent. General assistance, such as digging holes or clearing trees from a plot area, is permitted. Mixing product, treating plots or determining block damage (reading) is not allowed.

The USFS offers installation and reading of plots using the groundboard (GB), concrete slab (CS) and stake methods, as well as pesticide residual soil sample collection. Both the GB and CS methods are tests for soil barrier efficacy. The stake method is a slightly different barrier test for wood embedded in treated soil, and has not been requested for decades. All three methods are identical to those required by the EPA’s Office of Poisons, Pesticides and Toxic Substances (OPPTS) 810.3600 document. This document requires efficacy data for candidate termiticides for five years. Therefore, from product installation to completion, these studies take six years. Annually, the USFS provides product manufacturers with updates on their product’s performance. The EPA, as well state regulatory agencies (once the product obtains federal registration) are free to contact the USFS regarding the data or methods used to obtain them.

TEST METHODS

The OPPTS 810.3600 specifies two protocols for testing these products: the GB test and the CS test. The stake method is not mandatory, though it can be requested by cooperators. Ten replicates of each concentration (including water-only controls) are installed for each candidate termiticide in each of the three national field sites.

The methods are described in the annual termiticide report each year published in PMP magazine. Because no procedural changes have been made, the language used to describe them remains relatively constant.

For the GB test, a 17- by 17-inch area is cleared of debris, roots and rocks, and is treated with the candidate termiticide. After drying, a 6- by 6-inch square pine sapwood board is centered on the exposed, termiticide-treated soil, and held in place with a brick.

The CS test, also known as the modified groundboard test, is very similar. In this test, the treated plot area is also 17- by 17 inches square and cleared as previously described. After treatment, the soil is covered by a polyethylene vapor barrier, and a 21- by 21-inch concrete slab is poured around a 4-inch diameter PVC pipe placed at the center. Once the concrete has set, the vapor barrier is cut out and removed from the bottom interior of the pipe, and a 3.5- by 2.5- by 1.5-inch rectangular pine sapwood block is placed on the treated soil at the bottom of the pipe. To prevent weathering of the treated soil, a PVC cap is placed on the pipe. Completed plots form a grid in the forest.

For both methods, solutions of candidate termiticides are applied to the soil at the pre-construction rate of 1.0 gallon per 10.0 square feet (or 0.2 gallons per 17- by 17-inch square plot). For each plot, the wood is evaluated annually for termite damage using a simple scale called the Gulfport scale, and the presence or absence of live termites infesting test blocks or boards is noted.

THE GULFPORT SCALE

Damage data are collected using the Gulfport scale: 0 = no damage, 1 = nibbles-to-surface etching; 2 = light damage with penetration; 3 = moderate damage; 4 = heavy damage; and 5 = board or block destroyed.

The Gulfport scale has been used since the late 1930s by the USFS termiticide unit to give an estimate of the level of termite feeding on wood recovered during the reading phase of the studies. The scale has been described previously by Arthur F. Verall in 1959 (Forest Products Journal 9(1): 1-22).

The Gulfport scale can be compared to other termite-feeding standards scales, such as the ASTM scale first described in standard D 3345 – 74 (1974). Figure 1 shows how these scales compare. Note that at one time, ASTM International added a 9.5 rating. That rating does not appear in the most recent update from 2017 (D 3345-17). Regardless, the 9.5 rating did not alter how the Gulfport scale converts, so 9.0 and 9.5 ASTM were both roughly equivalent to Gulfport 1.

Although both feeding scales are categorical, termite damage does not jump from one of these conditions to the next in nature. The block ratings also are not evenly distributed across these categories. This is partly due to the breadth of the categories, with Category 3 representing both a large portion of the potential block damage, as well as the largest portion of study data each year for products reaching end of life date.

While it might be possible to make statistical comparisons using non-parametric methods, these are unnecessary, as the standard established by the EPA is a pass/fail system. The categories can, however, be important for state regulatory standards. Florida, for example, sets percentages of allowable damage to blocks. A more accurate representation of termite feeding would be to measure wood block mass loss, but this would be difficult to measure accurately in the field.

SOIL SAMPLING

Since 1998, the testing program has included extra GB and CS plots for pesticide residue analysis at each concentration level of a newly installed product. Soil sample cores are 1 inch in diameter and 4 inches in length, collected both after installation and on each subsequent year of the study.

The GB and CS plots designated for soil samples have no wood blocks and are not read for termite feeding. The soil samples are shipped to the product manufacturer for residue analysis of their product. Manufacturers can analyze the samples or not; the results of those samples are not shared with the USFS. For this reason, none of the soil sample data appear in the annual termiticide report.

PERFORMANCE STANDARDS

As has been reported in previous annual termiticide reports by the USFS in PMP, there is a single standard for federal registration under the EPA, under which each state can create its own standard. Under the EPA guideline, a candidate termiticide should prevent termites from penetrating treated soil in all (100 percent) test plots for at least five years.

To meet this standard, all wood specimens must be rated “0” for termite damage under the Gulfport feeding scale. The EPA’s guideline is a tough standard for product performance, and the EPA may register products that do not strictly adhere to its efficacy guideline (see PMP, May 2015). The lead agency for structural pest control in each state makes decisions regarding the use or sale of a product via either a state-specific regulatory standard (such as the Florida Termiticide Efficacy Rule, 5e-2.0311, FAC), or its own judgment of the USFS efficacy data on the product. Currently, 39 of the 50 state lead agencies choose to make these decisions collectively through the Association of Structural Pest Control Regulatory Officials (ASPCRO).

For the FS annual termiticide reports, the data in Tables 1 and 2 are presented for each site individually, as evaluated using the EPA guideline, and as an example of a state standard, the Florida Rule (individually by site and collectively across all southeastern sites). Discussions of the differences between the two standards have been covered in many of the past annual reports (PMP, April 2016 and earlier).

CONCLUSIONS

The USFS is now in its 10th decade of providing unbiased candidate termiticide efficacy data for federal needs (military or regulatory). Currently, this program has provided termiticide performance data for all federally registered products, and has provided these data to PMPs and homeowners via this report. This information enables people to make informed decisions concerning the protection of wood in service from termite feeding. It also helps pest management companies make decisions about termiticide products to offer their customers.

Editor’s Note: For the charts above, the data for the program that can be made public at press time have remained the same since they were first printed in the March 2015 issue of Pest Management Professional magazine. Please note the inclusion of brand names and manufacturer names are for data purposes only, and does not Imply endorsement by the USDA-FS.

DR. SHELTON is a supervisory research entomologist, FYE is a biologist, BELL is a biological science technician, DR. TANG is a research forest products technologist, and DR. MANKOWSKI is a research entomologist.

All authors are with the USDA-FS Forest Products Laboratory, Durability and Wood Protection Research Unit, Starkville, Miss. Contact them at pmpeditor@northcoastmedia.net.

Leave A Comment