ILLUSTRATION: CHIARO85/ISTOCK / GETTY IMAGES PLUS/GETTY IMAGES

When the coronavirus pandemic began, the professional pest control industry established a role in preventing the spread of the COVID-19 virus and other infection outbreaks. Many companies quickly adapted their hand sprayers and ultra low-volume (ULV) foggers to disinfect contact surfaces in public spaces, schools and workplaces. Technicians were reassigned and fitted with the required personal protective equipment (PPE) to take on disinfection.

But application methods have been a learn-as-you-go process over the past 12 months, and disinfection may be needed for a long time to come. Now is a good time to review how to use foggers and sprayers for disinfection, along with common misapplication methods that need to be corrected. These habits are costing you time, money — and possibly customers.

The objective of ULV fogging with disinfectants is to create a uniform coverage of droplets on the target surface. The small droplets will remain for the required contact or kill time for the disinfectant, which is usually 10 minutes, and then they will evaporate. Handheld ULV foggers are designed to deliver droplets to surfaces to meet this objective, but these machines require a skilled operator.

Disinfection fogging is based on equipment, science and planning; without these resources, it can be wasteful and ineffective. Here are three common application habits to correct and avoid:

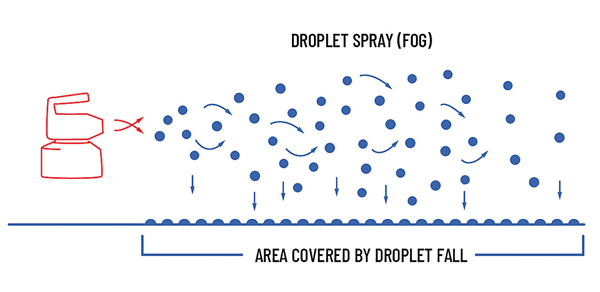

Figure 1. Randomly waving the fogger back and forth prevents surfaces from being effectively disinfected. FIGURE: COURTESY DR. WILLIAM ROBINSON

BAD HABIT NO. 1: THE WAVE-AROUND

The wave-around is the most common application method error because the product is not applied precisely on target surfaces; it is applied where it’s not needed. Surfaces are not adequately treated because the droplet plume is moved randomly, and no uniform residue is established. Oftentimes the air space is not treated because the droplets are too large and quickly fall to the ground. Some surfaces will become wet to the point of runoff, and the non-target surface — the floor — will get most of the disinfectant. This is the costliest and least-effective application method. Consider the following:

- ULV fogging the air space will not remove airborne microorganisms unless very small (10 microns) droplets are applied. If the droplets from the nozzle are visible, it’s likely they are too large (50 microns) and will fall to the floor within 40 seconds. They do not remove germs on their way up or their way down, but they will land on non-target surfaces and waste product.

- Waving the fogger randomly back and forth also prevents an effective disinfection of surfaces (see Fig. 1). Droplets from ULV foggers are carried on a strong airstream. The droplet plume extends about 12 feet from the nozzle, and 4 feet wide at about midpoint. Droplets fall from the plume over its entire length and width to create a treated surface below.

Proper application begins by setting the fogger for medium or maximum output. Hold the fogger so the plume is over the target surface for 15 to 30 seconds. The objective is to create a droplet residue. A uniform droplet residue will remain for the required contact time and then evaporate. Applying the product for longer than this is wasteful.

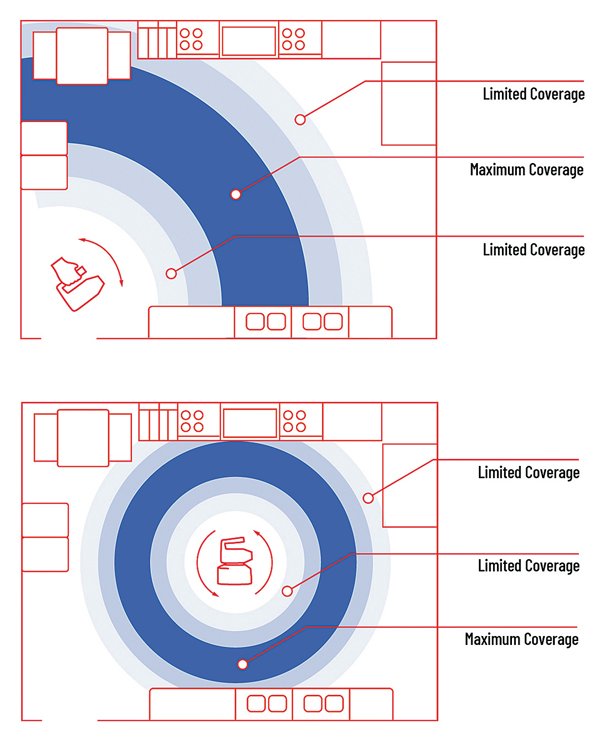

Figure 2. Product is delivered to surfaces beneath the droplet plume of the fogger. The time, in seconds, the plume is held in place determines the density of the droplets on the surfaces. FIGURE: COURTESY DR. WILLIAM ROBINSON

BAD HABIT NO. 2: STAND-AND-SPRAY

Attempting to treat the entire room by standing in one place and pointing the fogger at the ceiling is completely ineffective. Directing the droplet plume at the ceiling will not result in treatment of all the surfaces in the room. Large droplets in the plume collect close to the nozzle and drop to the floor around the operator. The small droplets in the plume will be scattered by air currents in the room. Directing the plume above workplaces will result in wet and damaged surfaces below.

In addition, directing the fogger to the ceiling won’t allow the droplet plume to extend over target surfaces to create a residue. The misconception is that the entire plume is composed of small droplets, and they will disperse through the room. However, disinfection fogging requires identifying the critical surfaces and holding the plume above them to create a residue. Disinfection fogging must be thought of in terms of surfaces, not spaces (see Fig. 2).

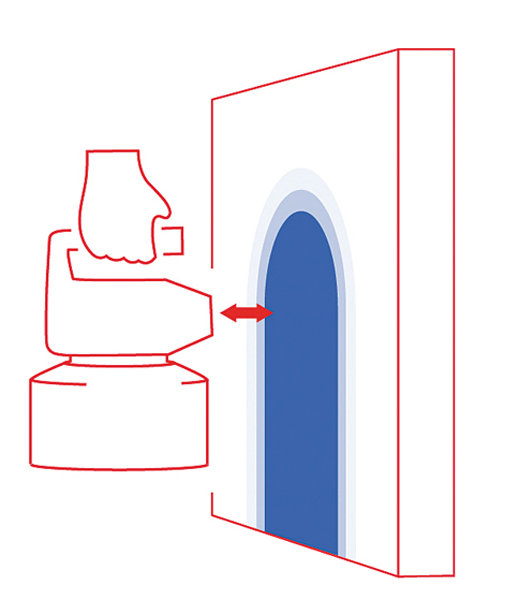

Figure 3. Spraying too close to surface will result in oversaturation

and waste. FIGURE: COURTESY DR. WILLIAM ROBINSON

BAD HABIT NO. 3: SEE IT, SOAK IT

Application too close to the surface will result in wetting to runoff and excess product use. The objective is accurate droplet coverage for the required contact time. Soaking the surface will not make microorganisms more dead, but it will waste product (see Fig. 3). A wet coating on surfaces will require cloth wiping, and that defeats the purpose of fogging and having the droplets evaporate after the kill time.

ELECTROSTATICS: DO’S AND DON’TS

Handheld ULV foggers with electrostatics (ES) can improve delivery and coverage, but cannot save a poor application. Another misconception is that an ES fogger pointed toward the ceiling will result in total coverage; it will not. This feature on a fogger can enhance a thorough and well-planned treatment, but it can’t save a poor application method.

Droplets with ES charge are most effective at 12 to 18 inches from the nozzle. Within this “threshold zone,” they deposit on the front and back of targeted surfaces. Once beyond this, the charge remains strong enough to influence droplet distribution on surfaces. Droplets with the same charge resist each other, therefore forming uniform coverage on surfaces.

Electrostatics will not improve the wave-around or stand-and-spray strategies for disinfecting surfaces in large spaces. Nor is it for air space disinfection; it will neither remove nor inactivate airborne microorganisms. In addition, soaking surfaces at close range with ES foggers is not needed: Wetting a surface is not more effective than creating uniform droplet coverage.

DISINFECTION FOGGING

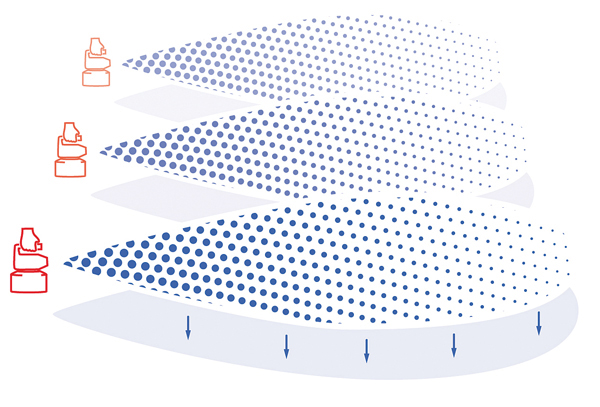

Understanding the operation of a ULV fogger and the dynamics of the plume of droplets is key to effective and efficient treatment. The plume may not be completely visible to the operator, but the air current is carrying droplets to the full coverage area (see Fig. 4).

Disinfection products are delivered to surfaces beneath the droplet plume of ULV foggers. The length and width of the plume determines the treated surface. The time, in seconds, the plume is held in place determines the density of the droplets on the surface. The operator controls the disinfection by timing and overlapping plumes to treat all target surfaces.

This is the science behind disinfection fogging: There is no waving, standing or soaking.

Read more:

- Cleanup crew: COVID-19 prompts PMPs to offer disinfecting services

- Pro tips for offering disinfecting and sanitizing services

- Answering emergency calls anytime, anywhere

- Reader poll: Effectively promoting disinfecting, sanitizing services

DR. ROBINSON is technical director of B&G Equipment Co.

Between foggers and sprayer pumps, which one is better for hospital disinfection?

Thank you for writing, Kefa. We reached out to Dr. Robinson, and here is his reply:

An ultra-low volume (ULV) fogger generally treats broad surfaces with small droplets, and treats them all the same, regardless of whether they need to be treated. For example, fogging a room for disinfection will treat all the exposed surface, including the floor. The floor is not a logical target or a contact surface, and thus does not have to be treated. The effective use of a fogger would be to direct the fogger to specific surfaces.

A pump sprayer using a fine-fan nozzle can deliver nearly the same amount (0.067 oz. / sq. ft.) of disinfectant to surfaces as a fogger (0.068 oz. / sq. ft.). The advantage of a spray nozzle is precision application, but it may take more time; the advantage of a fogger is time-savings, but less precision. There are surfaces and locations in hospitals and healthcare facilities that would benefit from ULV and spray application of disinfectants.